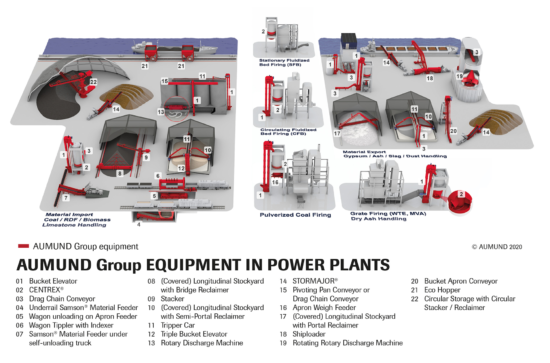

Power Plants

Sophisticated Products to Convey Material for various Firing Methods, Process Optimisation and Cost-Effective Solutions for Material Storage

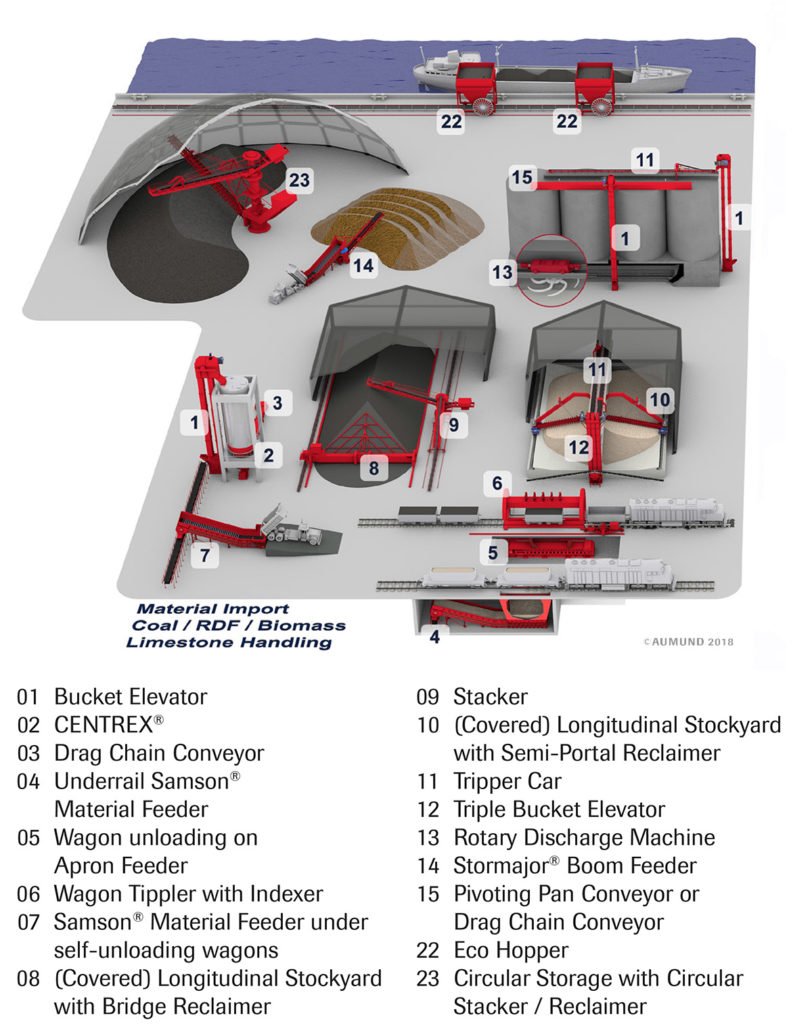

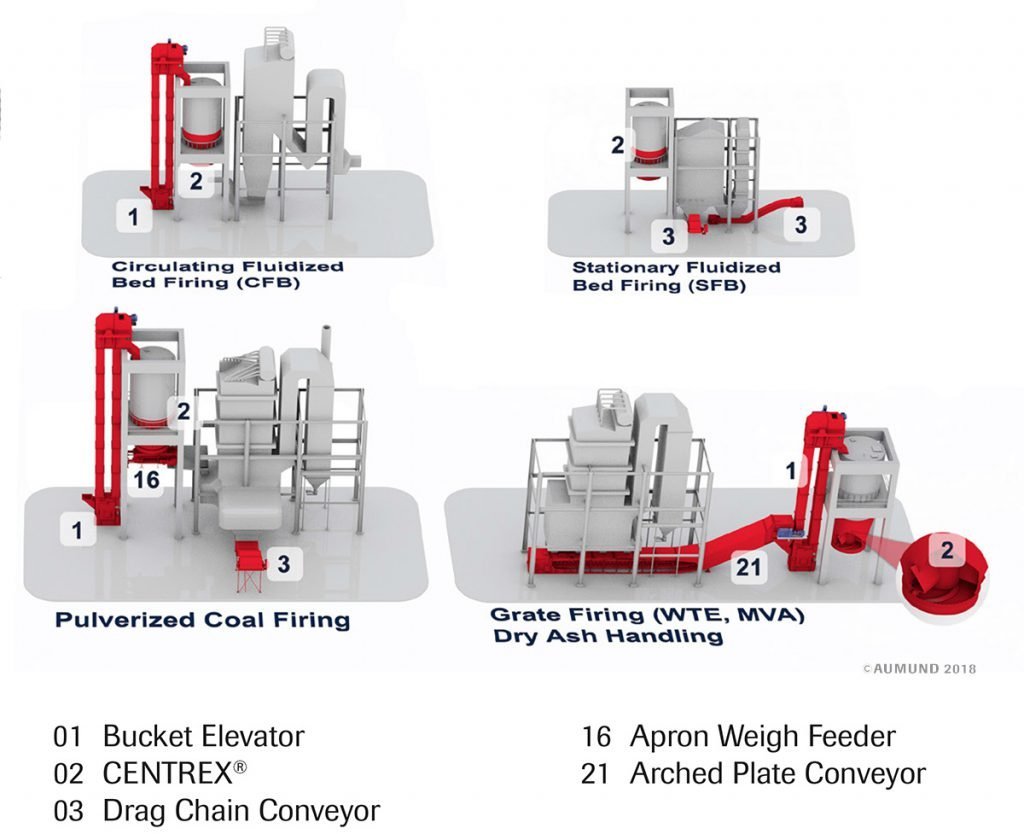

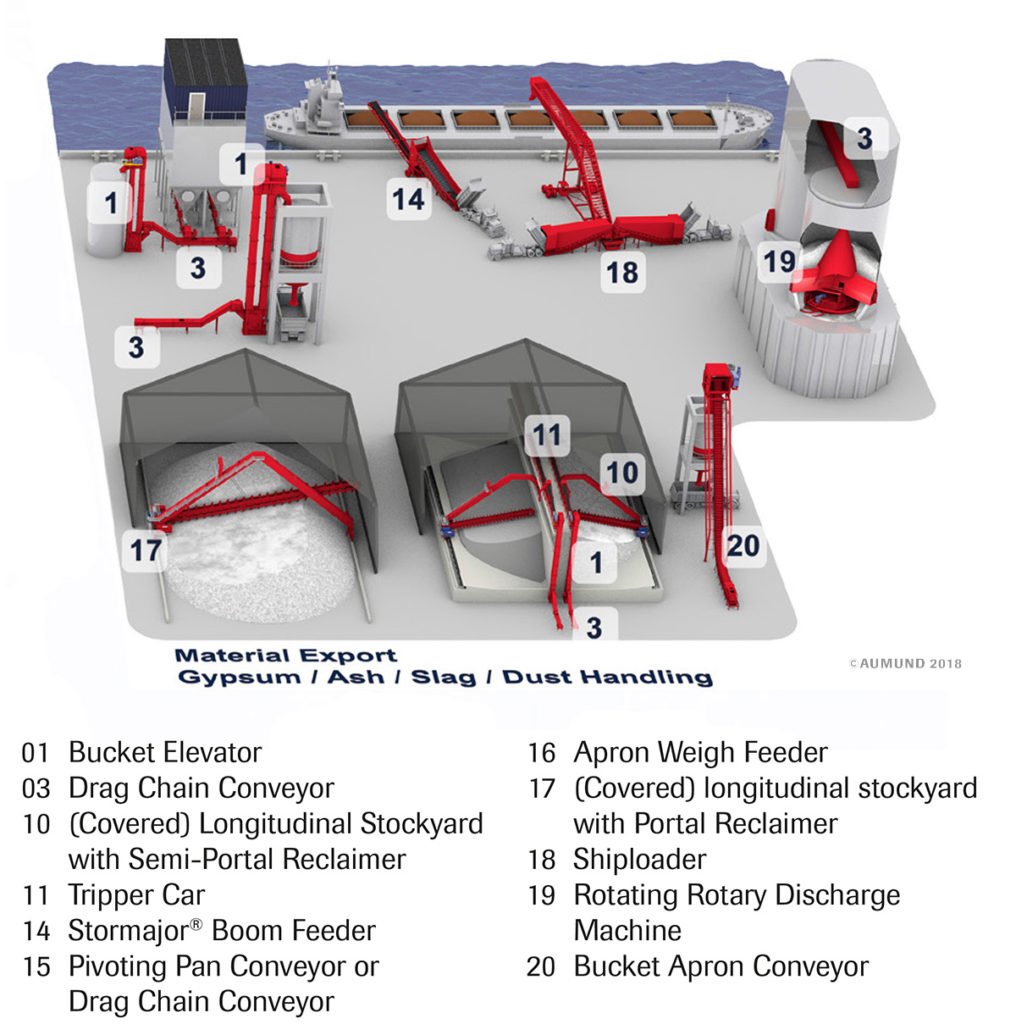

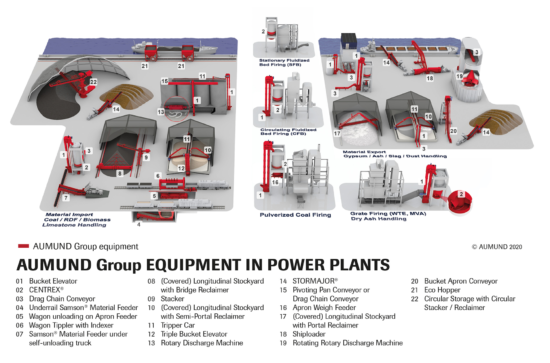

AUMUND Equipment is classed as essential in many areas of a power plant, such as for the intake of coal, RDF, biomass or limestone for different firing methods, and whether it is for grate firing, coal dust firing or fluidised bed combustion (CFB/SFB), and also for the output of gypsum, ash, slag and dust.

Many power plants run their material storage in a strategic manner, with buffer stockpiles of coal from different sources with varying quality. As well as strategic stockpiling, SCHADE Blending Beds are in operation in order to homogenise the raw materials to achieve a constant quality of input.

SCHADE Wagon Unloading Systems are available in various models, which can be adapted to suit different geographical regions and their climate zones, diverse wagon types and fluctuating handling volumes.

SAMSON Materials Handling offers a range of cost-effective solutions for the loading and unloading of rail wagons, road vehicles, barges, and ships up to Panamax size, by means of a combination of surface-mounted and mobile machines which can be integrated into the existing infrastructure of a power plant. For smaller power stations such as those which supply the electricity and steam requirements of an individual industrial plant, the flexibility of the Samson® Material Feeder concept offers considerable advantages with regard to location and manoeuvrability.

Products and Solutions for Material Intake:

Products and Solutions for Firing Methods:

Products and Solutions for Material Output:

- Bucket Elevators

- Pan Conveyors

- Chain Conveyors

- Chain Bucket Elevators

- Discharge Systems

- Loading

- Samson® Material Feeder

PRODCTS & SYSTEMS

Flowsheet

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

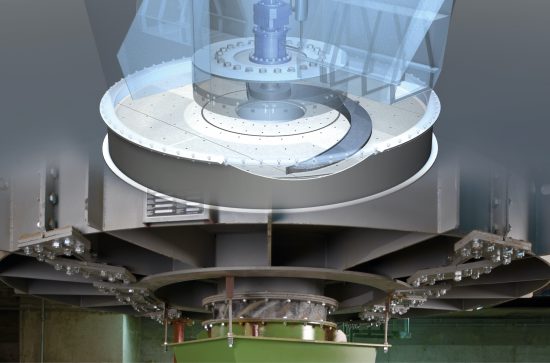

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader