Circular Storage

Internationally proven Circular Storage Systems as stockpiles and blending beds – with Stackers, Bridge-Type Reclaimers and Semi-Portal or Portal Reclaimers to blend the bulk material

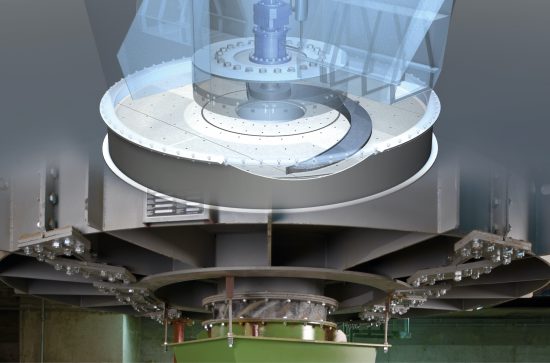

The constraints of having high volume storage requirements but with restricted space available are increasingly being resolved by circular storage concepts. SCHADE is one of the forerunners in this development and has many excellent international references to show for it.

- Stockpiling usually with Slewing Stacker

- Stacking using the cone shell method

- Reclaiming the stockpile from the inner slope with a Cantilever Reclaimer which can be designed as a Lateral, Semi-Portal or Portal Reclaimer

- Reclaimer with double strand chain and wear-resistant shovels

- Central discharge via chute

- Simultaneous stacking and reclaiming operations, completely independent of each other to optimise the flexibility of fully utilised storage capacity

- Storage diameter can be greater than 120m

- Storage volume over 180,000 t

- Stacking capacity above 4,000 tph

- Reclaim capacity above 2,000 tph

Circular Storage offers a combination of relatively small space requirements and high storage volumes. It has become one of the major areas of expertise of SCHADE Lagertechnik in recent years.

Design variations

- Combined Stacker and Cantilever Reclaimer

- Combined Stacker and Lateral Reclaimer

- Combined Stacker and Portal Reclaimer

Functions and characteristics

- Stacking using the cone shell method

- Reclaiming the stockpile from the inner slope

- Reclaimer with double strand chain and wear-resistant shovels

- Bulk material conveyed to a central discharge chute

- Simultaneous stacking and reclaiming

- Stacking and reclaiming is PLC controlled (automated operation)

Combined Stacker/Reclaimers for outdoor stockyards were traditionally supplied by SCHADE to the chemicals industry. Later came installations for limestone storage in cement plants, and more recently for stacking and reclaiming wood pellets in the pulp and paper industry.

More stringent environmental regulations have led to a considerable increase in demand for covered storage in recent years.

The first Circular Storage with combined Stacker/Reclaimer was designed and built in 1988, to store 95,000 mᵌ of coal on a 97m diameter stockyard. Some of the largest SCHADE machines are 9 Circular Storage installations in Taiwan. These storage buildings were commissioned between 1997 and 2002 and are 120m in diameter. They achieve stacking capacities of 4,000 tph, and reclaiming can reach rates of 2,000 tph.

SCHADE develops recognised concepts all over the world for Blending Beds with optimum mixing or homogenisation of the stored bulk material, by equipping the plants with combinations of Stackers and Bridge-Type Reclaimers.

The Stacker constitutes the stockpile as a Blending Bed, and the Bridge-Type Reclaimer homogenises the material during reclaiming. It collects the bulk material which is continuously loosened by the harrow scraping along the end face of the pile. The rotating scraper chain, which is mounted on a torsion-resistant supporting structure, conveys the material into a central discharge chute. Operation is monitored and controlled by a PLC and is fully automated.

Products & Systems

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader